DIY Pulse Capacitors

You don't need lots of money to make high voltage capacitors, in fact some pretty decent ones can be made with some cheap and readily available materials. This is because capacitors are very simple devices consisting only of a dielectric and two plates, and most often a capacitor's plates are just aluminum foil. Reynold's wrap is easy enough to obtain, but what about the dielectric?

If all goes well you should end up with a capacitor that ought to be good for about 50kV. Typically these home-made caps will have a capacitance of about 3nF as can be seen by this LC meter’s screen. That’s definitely not too shabby considering a capacitor such as that would cost you $40 surplus.

If all goes well you should end up with a capacitor that ought to be good for about 50kV. Typically these home-made caps will have a capacitance of about 3nF as can be seen by this LC meter’s screen. That’s definitely not too shabby considering a capacitor such as that would cost you $40 surplus. Keep in mind that this capacitor is not as robust as a commercial one due to the inclusion of air between the plates and the dielectric. Yet, if you soak the assembly in molten beeswax and simultaneously pull a vacuum the air will be replaced with wax and make a much more robust capacitor. Some sort of modified pressure cooker could do the task, but that’s another story for another day.

Keep in mind that this capacitor is not as robust as a commercial one due to the inclusion of air between the plates and the dielectric. Yet, if you soak the assembly in molten beeswax and simultaneously pull a vacuum the air will be replaced with wax and make a much more robust capacitor. Some sort of modified pressure cooker could do the task, but that’s another story for another day.

The Dielectric

Enter the overhead projector sheet. Transparencies as they are commonly known as are nothing but acetate film, and while this is not the ideal dielectric for a capacitor it still does quite a good job. Typically a 4mil OHP sheet can withstand 14kV before breaking down

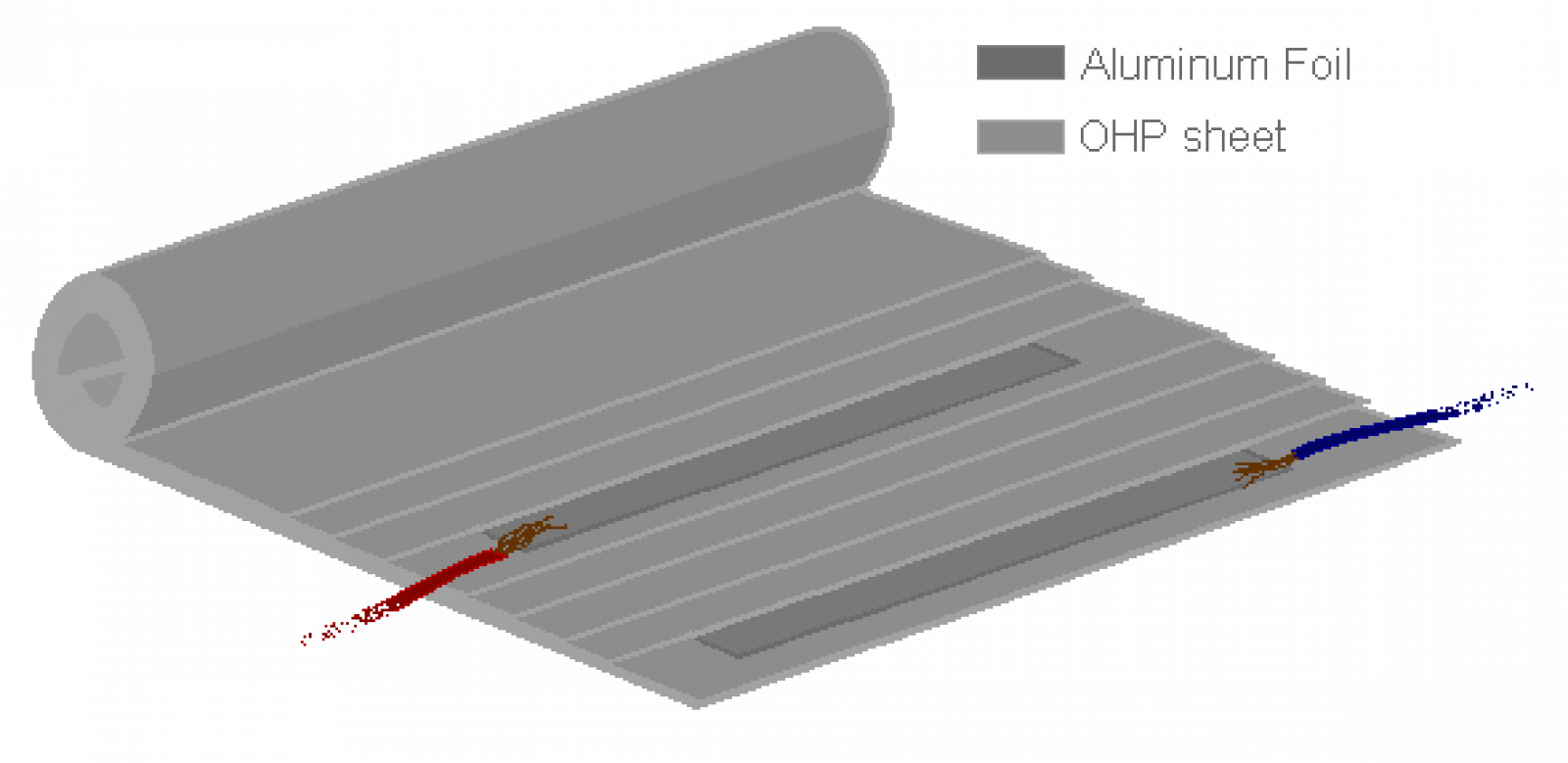

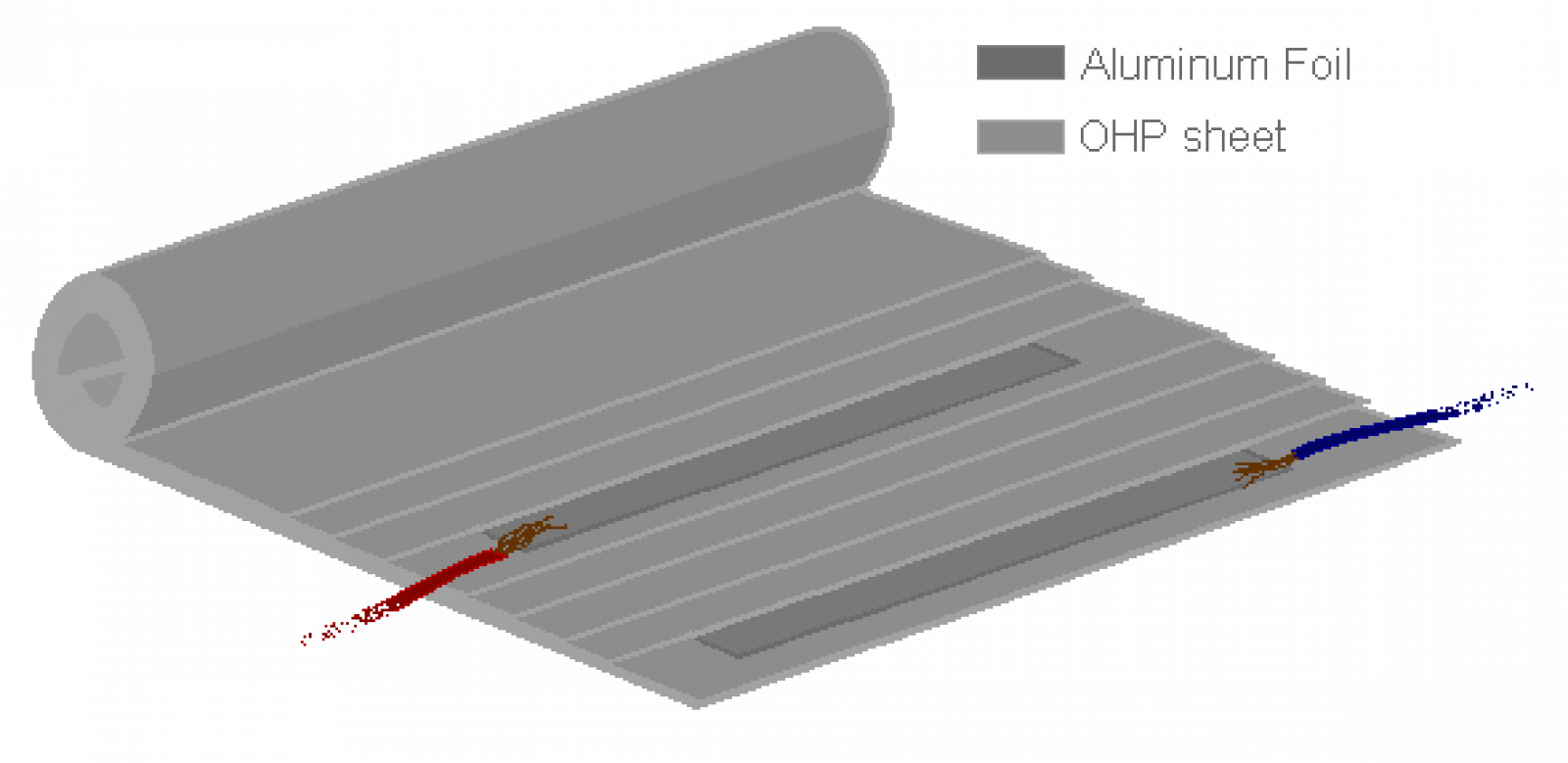

Construction

How you make the capacitors is a rather trivial task, all that needs to be done is some cutting, flattening and rolling. Here I have an image that explains the process. Multiple sheets of OHP sheet are used to increase the capacitor's voltage rating, and two sets of sheets are used so the capacitor can be rolled up.Some tips:• Use a rolling pin to flatten the foil.• Roll the cap up very tightly.• Use thin wire to minimize trapped air.• Secure using zip-ties• Leave 4cm between the edges of the OHP sheet and the foil to prevent flashover.