Originally owned by the Icelandic ferry service Finnmark Fylkesrederi og Ruteselskap, the vessel “Tufjord” had in 2001 found its way into the hands of a Californian architect, Olle Lundbgerg.

Olle has a fascination with reuse, salvage, and breathing new life into old spaces. This ship, at the time for sale at auction, looked like a wonderful opportunity to express this creative muse in a remarkably unconventional way.

Olle had the vessel restored to a seaworthy state in Iceland where it was modified to make a journey its designers had not considered –a trip across the Atlantic, through the Panama canal, and up the western coast. It was a trip that required new hardware and a crew with significant experience, but was ultimately made safely from the icy Nordic seas to the calm harbors of the Golden State.

The ship found its new home at the port of San Francisco a much more temperate one than the frigid waters of the arctic. It was a place to start fresh, where the diesel-fired heating systems and 70’s vogue fashion was cleared out to make room for stainless steel furniture, wood-burning stoves and a lovely cyprus table.

Staying true to the spirit of the project, nearly every new addition to the vessel was made from reclaimed materials from Olle’s past adventures.

For several years he had shared the ship as a studio with his wife, entertaining curious residents of San Francisco with the architectural marvel it had become.

Yet eventually there came a time where bigger, more ambitious projects such as Twitter’s office had come to overtake the hours Olle could give to the adventure, and the ship was offered for sale yet again to another crew of ambitious people.

It didn’t take long for those ambitious people to arrive, and the ship was purchased by a rocket scientist, a software architect, and a prolific librarian.

These three engineers couldn’t help but find the opportunity to host such a fantastic piece of machinery intoxicating, and soon became new new stewards of the MV Maritol.

For some time thereafter the ship had seen life as a social club, event venue and co-working space, 2), where it catalyzed young projects such as Matterport and OpenROV during its tenure. It became a venue for social cruises of the Internet Archive and other e-scalawags, and for a brief moment was even heated by crypto-currency mining.

But as all boat owners eventually discover, vessels require constant maintenance to stay in good health, and slowly but surely the war on entropy started looking bleak.

As anyone who is familiar with salted roads can understand, brine has a way of making holes in steel. This is not only true for cars but for ships as well, and eventually there come times in every boat’s life where even corrosion prevention systems get overwhelmed with nature’s quest to oxidize everything.

Everything it did indeed!

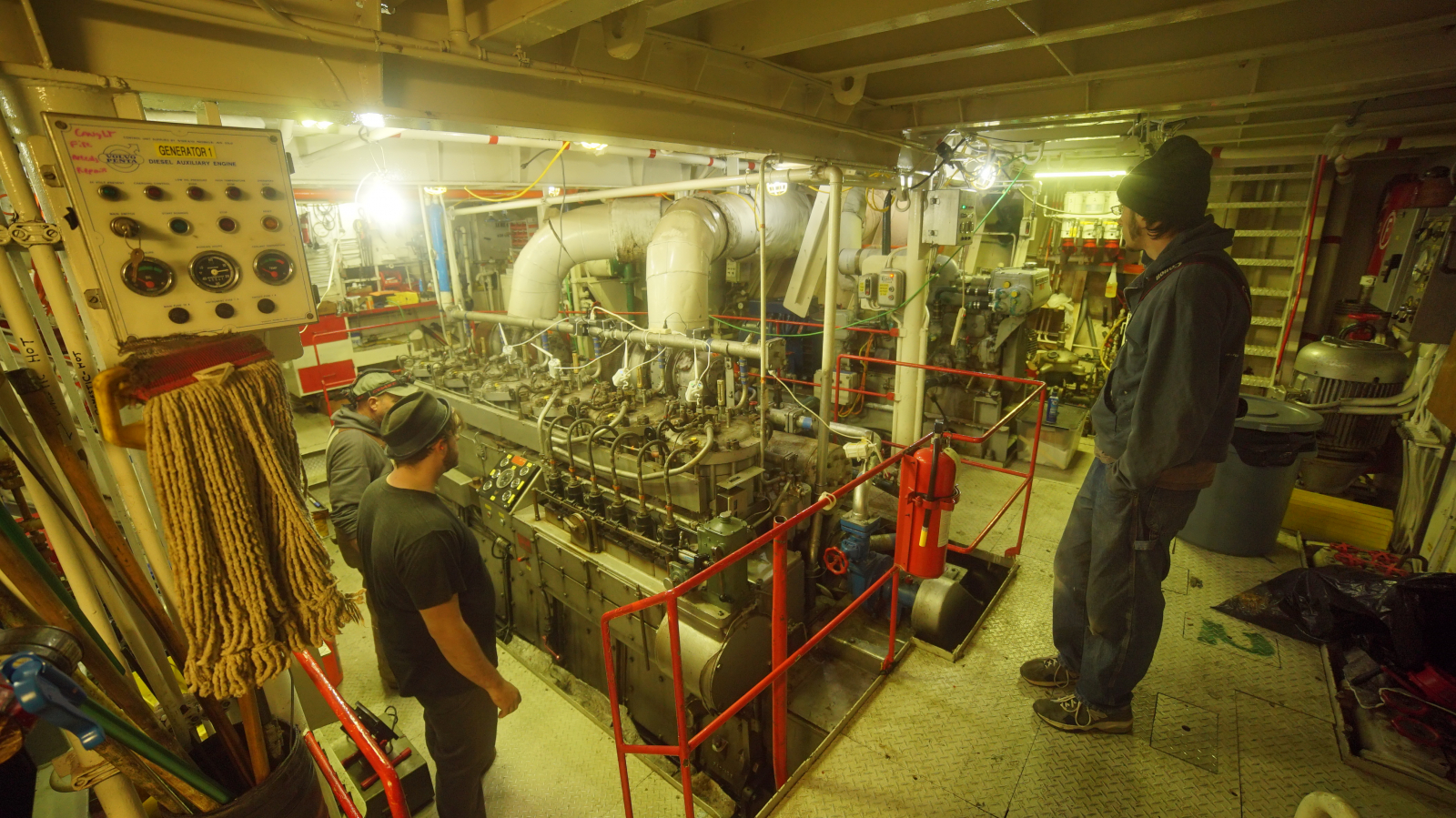

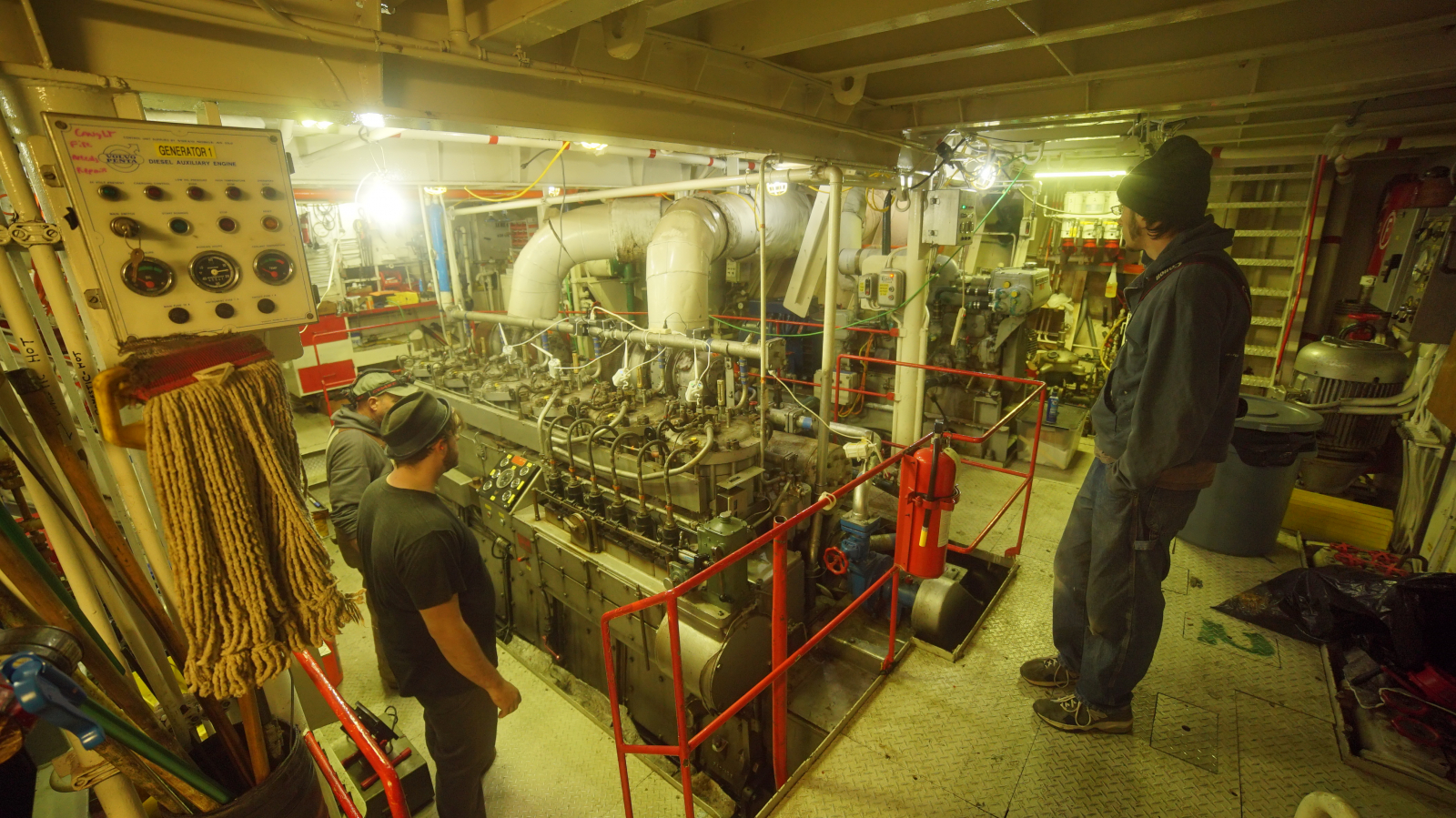

It was about this time the vessel had entered our stewardship, when countless valves, pipes, fittings and motors had seized in the short while it had not been in active duty. Much of the vessel’s original crew had at that point moved on or passed away, documentation was limited and scattered, and it wasn’t even clear if the engine could run anymore without harming itself. It looked like a puzzle of ultimate proportions –and a fun adventure indeed.

Of course, none of us of really knew very much about ships or even engines, but problems are just knowledge you haven’t learned yet.

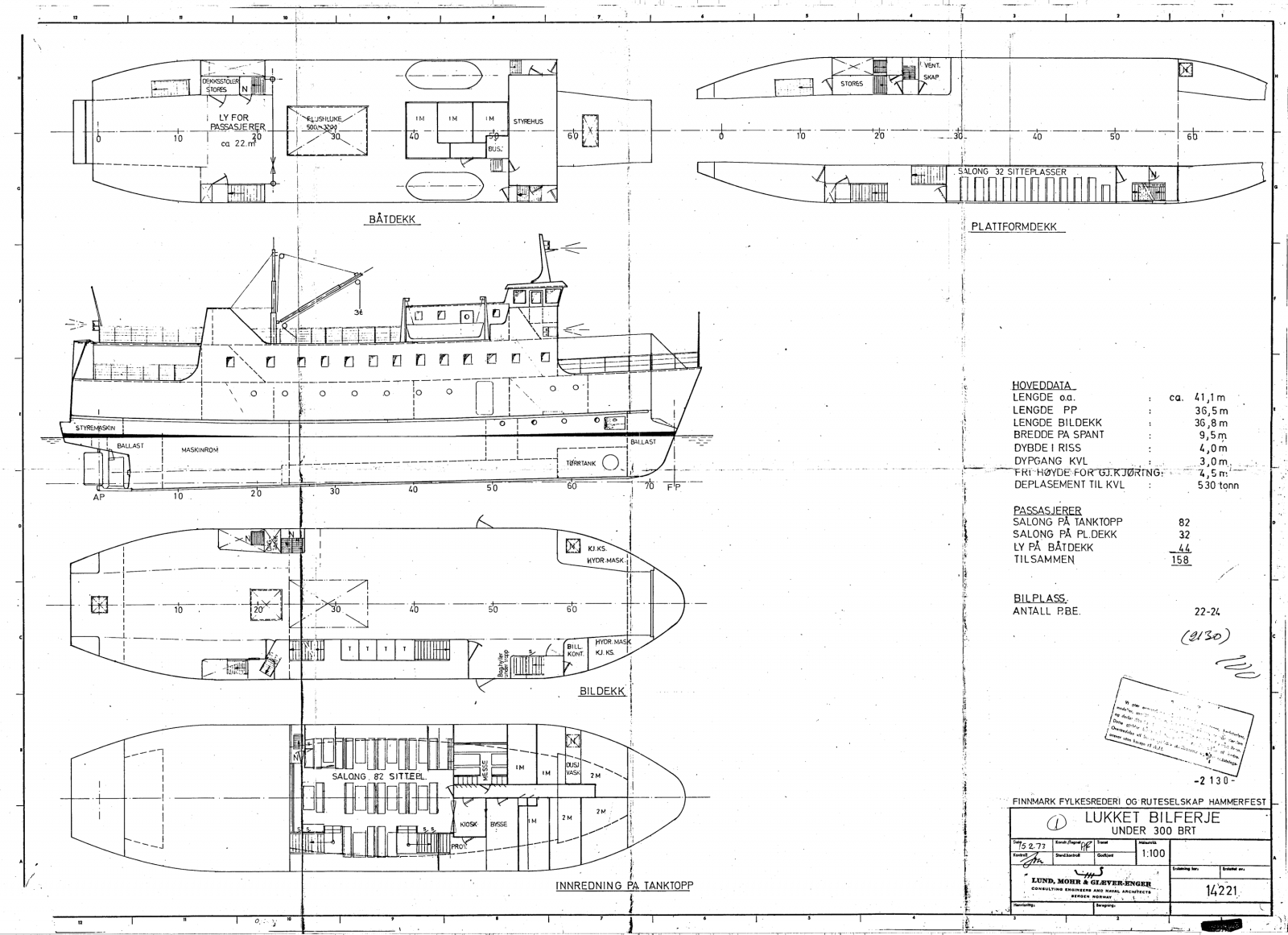

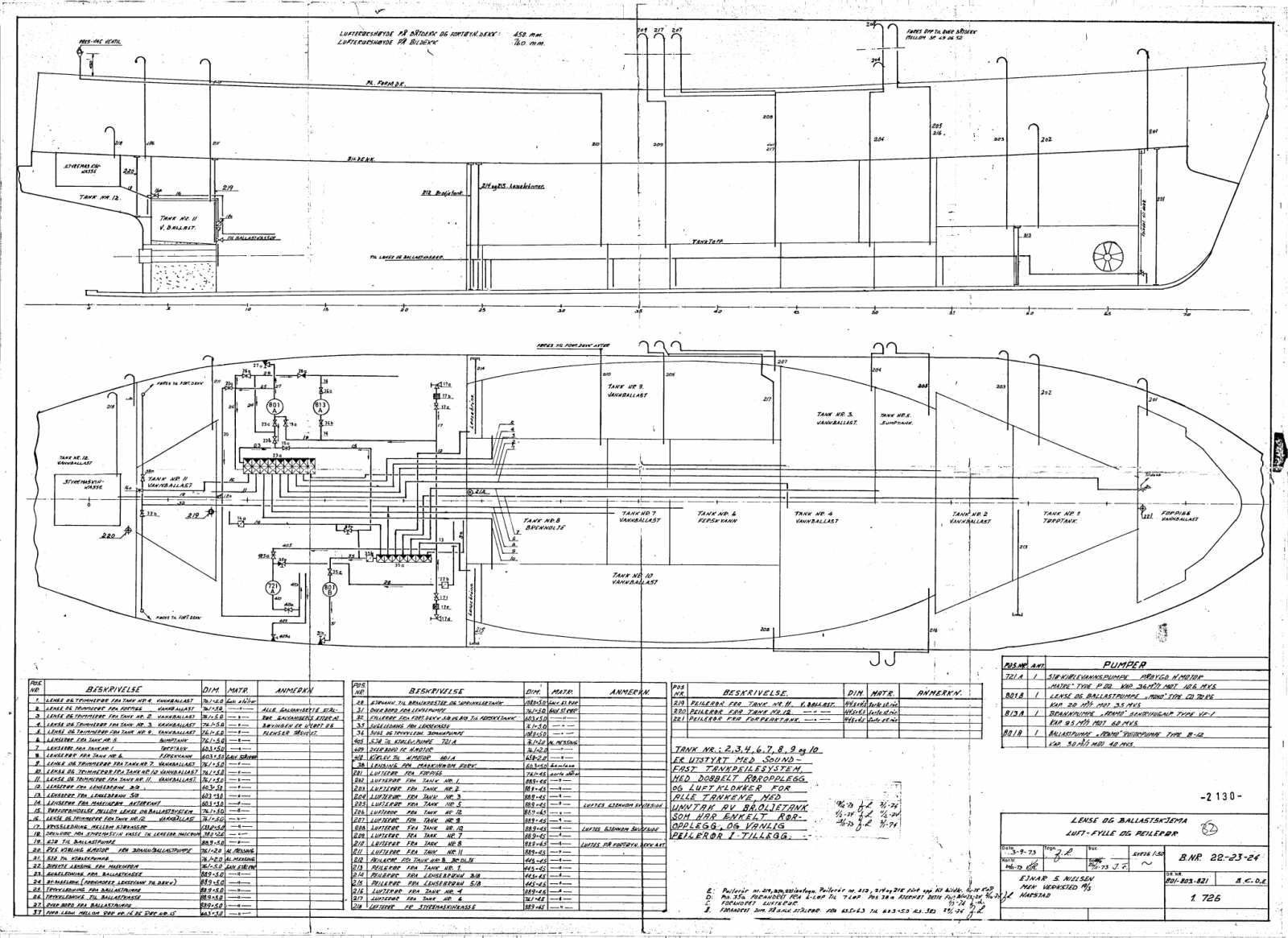

Over the the next few months we sought to understand how the vessel was constructed, and why it was designed the way it was. Some of the most interesting features we found are that:

- The vessel is powered by a 1 megawatt two-stroke diesel engine with six cylinders, twin turbochargers and roots blowers. Its fuel is fed by gravity from a series of large tanks.

- Electricity (up to 90kW) is provided by auxiliary volvo diesel engines, to be run exclusively of each other.

- All of the critical control systems are run by air-lines, to ensure the engine can be operational in the event of power failure.

- Engines are started by air, which can be manually compressed in exigent circumstances.

- Forward and reverse propulsion is achieved by a variable pitch propeller and single reduction gear.

- Lateral movements can be made with a hydraulic-motor bow-mounted thruster.

- Balance is achieved manually through a ballast pipe manifold and electric pumps.

- Cooling is provided by sea water through heat exchange loops.

It became clear to us that much of the design of the ship was done so with redundancy in mind. Where installing two of something was not practical, often half of something could be used to get the job done –even the main engine could have cylinders disabled and still run! Design choices in a ship are not made not through economic frugality, but in respect of the blood of lost sailors in the years we’ve been a seafaring species.

Around early May, we had fixed a much of what was broken and had the boat running once again. It took many months of dedicated effort to untangle the web of mysteries, and at least 3 and a half 55 gallon drums of eblow-grease and engine oil to get the vessel sailing once more.

With systems functional and Maritol running again under its own power, it was time to cast off the lines and set sail for Vallejo.

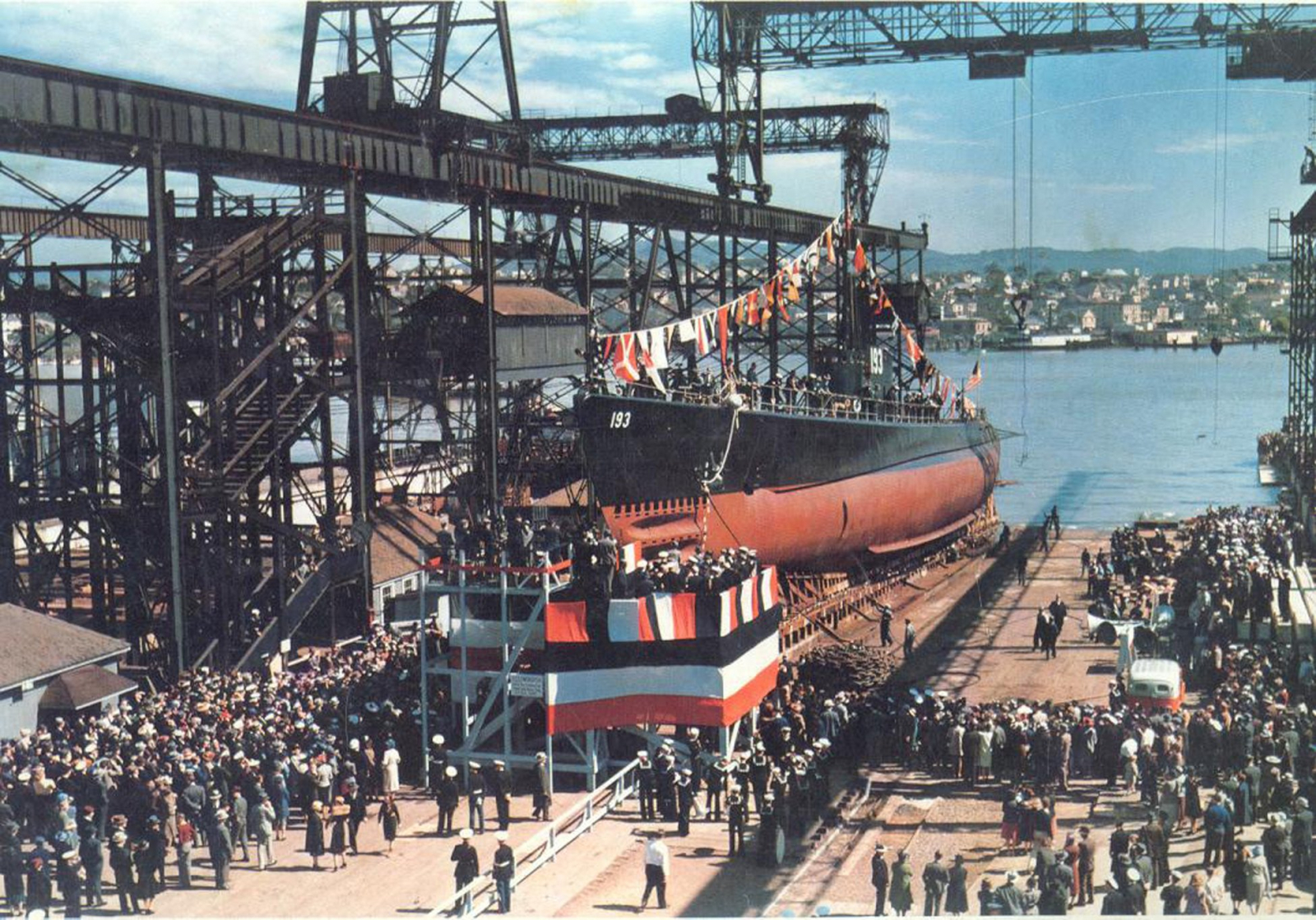

Vallejo is a sleepy little town with a rich history. Not too far from San Francisco, it made a name for itself as the host of one of the busiest shipyards in the USA. Back in the olden’ days when America was a place where no project was too big, the Mare Island Naval Shipyard christened more new vessels than anywhere else in the country. At peak it was employing 50,000 people and producing a new vessel nearly every month.

The shipyard slowly fell into disuse over the years, then was sold to a private business which continues to operate a portion of it restoring and preforming maintenance work on large vessels.

We had shown up a bit earlier than scheduled and had some time to explore the yard and its beautiful construction.

The first thing anyone might notice about such a shipyard is its scale. The size of the docks is particularly striking, we’re not in Kansas anymore!

To work on the contracted ships, millions of liters of water are pumped out of a lock, to allow the vessels to settle on “blocks” which are previously put in place with a crane. It’s the responsibility of the shipowners to tell the dock where these blocks should be and what their geometry is, and the responsibility of a diver to inspect under the muddy water whether or not the vessel is in landing in the correct spot.

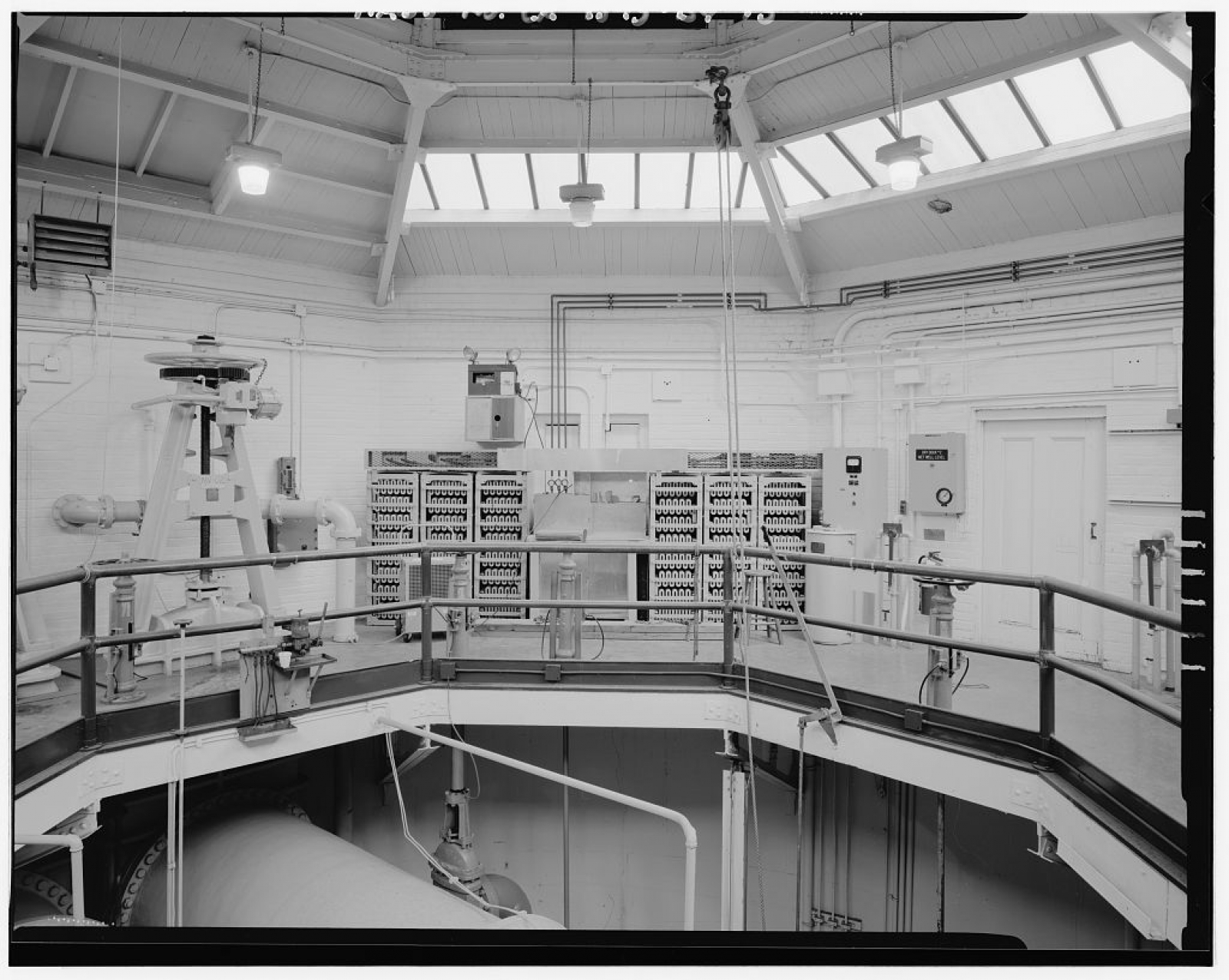

The water is pumped out by massive pumps, which in the case of Mare Island are beautiful pieces of electrical artwork constructed a hundred years ago. The same woman has been running the pump-house for decades, and is a lovely gal who’ll gladly give you a tour if you have the curiosity to ask.

The whole place hasn’t changed in the slightest since the Library of Congress photographed it in 1933, it’s truly remarkable that the same equipment has been in use for more than a century.

Mare Island itself is filled with an explorer’s treasure trove, such as a lovely museum of radiography and non-destructive-testing, bits & pieces of old military hardware, abandoned hospitals and abandoned military barracks. It’s an exciting place to go exploring if you ever have the chance, certainly before it gets turned into another plot of the exclusionarily-zoned McMansions California is so fond of building.

While waiting for our spot in the shipyard, we began working on removing parts of the ship we didn’t want to be included in the final finish. In practice this mostly meant, “remove things which were rusty beyond repair”.

Working on a ship has a way of refactoring your understanding of what is considered “immutable”. When everything is made from steel, you begin to see steel as a malleable and pliable material rather than as something sturdy.

In fact you begin to appreciate why we choose to make things out of steel. It’s a very nice material that cuts, joins, and bends easily with the correct tools. If it weren’t for the unfortunate fact that inexpensive alloys rusted easily, it would be the perfect building material indeed.

Upon arrival of our cohabitants, the Pebble Beach[/i] oil tanker and San Francisco Belle[/i], it was our time to enter the locks. Over the course of several hours the drains were opened and the lock was flooded with bay water, after which the lock door was pumped empty and towed by MV FatCat [/i]to a far off place.

There we waited to see what the ship looked like out of water, as none of us had seen such a thing before. Pumping out the water took several hours, but was put into suspense by “Fish Rescue Level 1”, a legally required two-hour operation where men in wader boots scoured the lock in search of endangered species. None were found, and 500 longshoremen went home with fatter paychecks that day.

There is something remarkable about seeing 300 tons of metal balanced on wooden blocks, with balance of course, being the only thing keeping it steadfast.

Balance and much to everyone’s amusement, a large selection of plants and under-sea animalia.

Everything below the water line was covered in sea critters of all kinds. It’s often the case that vessels are painted with toxic paint to prevent this sort of growth and indeed ours was originally. Life however finds a way, and so these creatures represent whatever life-forms were immune to the toxins leached by the “anti-foul” coating.

You might consider this at first glance to be somewhat of a bad thing, and indeed it is for the purposes of hydrodynamics and fuel efficiency.

For structures that are stationary though, such a coating can be very good for the purpose of protecting paint and can even be forced to accumulate by subtle electric current in the water, a construction technique known as

bio-rock.

Despite its rigidity, the coating was no match for high pressure water.

The process of painting a vessel traditionally begins with removing first the fouling, and then the old coating. The fouling is removed with water and no other blasting media, as everything in a dry dock must be treated as toxic waste in California. Using blasting media would increase cost further than just increasing the water pressure to immense levels. So immense, that the water atomizes to steam shortly after leaving the spray gun.

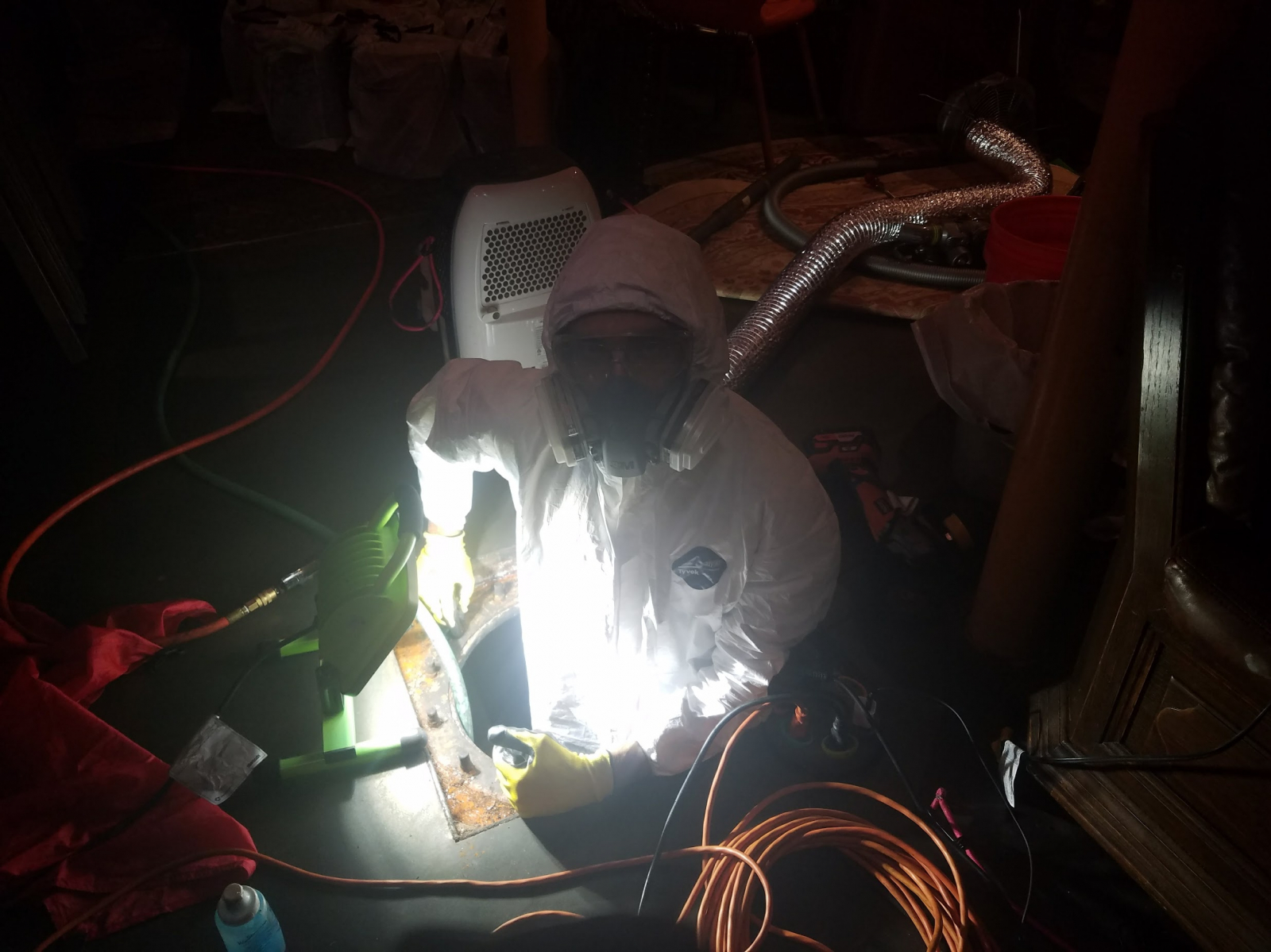

It didn’t take more than a few hours to have all of the fouling removed from the vessel, and for us to discover our first hole in the hull.

Remarkably, pinholes are a fairly standard occurrence when refinishing a boat’s hull. When steel rusts in a ballast tank, what often happens is the vast majority of the metal is left unharmed, except for small pits which slowly grow larger to eventually break through. The pits will rust preferentially to the surrounding steel as this is favorable electrochemically.

It’s usually not discovered that there are any holes at all until the paint and fouling is removed from the vessel, even if it has been there for years. Little did we expect though, that this hole would be a great deal of work to repair.

Steel ships are constructed with multiple “tanks”, which in reality, tend to be simply sections of the hull which have had steel plates welded in-place to segment them apart. The ideas behind doing this are numerous:

- If the segments are air-tight, punctures of the hull should not be fatal to the ship’s buoyancy.

- The segments can be used to hold unique fluids like oil, water, or fuel.

- The segments can be used to balance the ship by partially filling them with water.

- The segments can be filled or emptied to lighten on heavy the ship, to accommodate differing cargo masses and keep the ship at its most stable condition.

The tanks in steel ships are sometimes coated with an unpleasant coal-tar substance which acts as a barrier to corrosion. Oxygen dissolved in the tank’s water will otherwise slowly turn the steel into rust powder, but at a much slower rate with the coating than without. Modern ships tend to use epoxy coatings in place of coal-tar which are much easier to clean and service.

There are rules and regulations in the United States about how construction work is to be performed, most of which pertain to aspects of safety. One such rule is that anything qualifying as “hot work” cannot be done within a specified distance of anything flammable. It’s a reasonable rule however inconvenient it may be, as the last thing anyone would like is 10 barrels of fuel on fire.

To satisfy the safety requirements, we had to move fuel from a segment nearby the repair site to somewhere out of safe range of where the work was to be done, then clean the tank thoroughly such that volatile gasses were below specified levels. We learned after the fact, that in practice it is best to enter a ship yard with nearly-empty fuel tanks rather than full ones, to make such a job much easier.

The next step for the painting team was to break out their “ultra high pressure” system, a 40,000 PSI rotating water jet which sounds much like the child of a blender and jack-hammer, that blasts the rust off steel in a hurry.

It is quite a remarkable machine which concentrates the power of a massive diesel engine to spray water so strongly, that a small hole in the hose could drive leaking water straight through your finger. It’s not a child’s spray toy by any means.

In nearly no time at all, any and all rust was immediately vacated by its whirling might.

Traditionally, painting a ship is done in multiple phases.

The first phase is a priming phase, which is done with an epoxy that’s specifically tailored to mechanically bind to steel. Often this is a Bisphenol-A epoxy like most others, but with a reasonably high mixture of solids (60% or so) added to give the coating substantial thickness and surface roughness.

Afterward, the tougher layers of paint are applied by spray gun underneath the cover of plastic sheeting, to protect the environment from being painted as well.

The outer layers of paint are epoxy also, but contain soft additives such as aluminum to allow the paint to deform (but not crack) in the event that it becomes impacted. Much work goes into the study and development of self-healing paints, as paint is the first line of defense against the ocean’s caustic might.

On commercial vessels it is often favorable to put a final layer of “Anti-Fouling” paint on the underwater “Freeboard” hull to prevent sea life from growing and ruining its hydrodynamics. We opted to not put on this coating as our vessel is not used commercially, and it is better to not leach toxic metals into the San Francisco bay if it can be avoided.

Ships have many features whose purpose is not immediately obvious, such as these rails welded to the side of the hull.

Upon first glance you might think the purpose of the rail is to serve as a bumper or fender –and indeed, it does to some extent. However, its primary purpose is to actually provide a dragging force to rolling motion incurred by waves. “Bilge Keels” as they are known professionally, are one of many techniques used to stabilize ships in the high seas. Additional techniques include the use of active hydrofoil stabilizers and actively-pumped water ballasts, neither of which are installed on the Maritol.

Work doesn’t stop in a shipyard just because there are a few holes in a vessel –if a welding team needs to do some task, the painting team must circle around them!

The patching technique used here, “Doubling”, is a fascinating study in of itself, as ships tend to be made from steel which is of an organic shape. Thus, there are no off-the-shelf parts that fit the curvature of a hull perfectly.

Doubling is a multi-step procedure, where plates of appropriate size are tack-welded to the hull, then brutally forced into the correct geometry using hammered wedges and temporary fitments welded to act as something for the wedge to push against. The fitments are then ground off after bead welds are applied, to make room for a water-tight seam weld around the whole of the plate.

After painting is complete, it is traditionally time to fit new anodes onto a ship. Anodes are pieces of sacrificial metal whose electronegativity differs from the steel hull in such a way as to create a small voltage, whose presence makes corrosion of steel less favorable.

In ships that lack an active electronic corrosion prevention system, over the period of a few years anodes are consumed by the sea as payment for their protection (as I found, with a substantial current of approximately 70mA for a typical anode).

Our ship unfortunately had both no active corrosion protection system, and non-standard anodes, so we had to get creative by rapidly constructing a mold capable of holding molten zinc for custom casting.

Then afterward, fly it to our favorite local foundry in San Leandro that same evening to make their time-table, and ours.

We did succeed in the adventure, and installed the anodes in places where they are most important, such as the water intake port or “Sea Chest” for the engine, as well as the rudder, trim, propeller and bow-thruster cavity of the vessel.

With the anodes installed, there wasn’t much left to do in the dry dock. We took time to relax and explore, under the eerie orange glow of a local wildfire.

It’s hard to say that you’ve known “backbreaking work” until you’ve been a longshoreman. The restoration of this vessel was an intense experience, and I have great respect for people who work in shipyards keeping our world’s fleets afloat.

It’s hard to appreciate also, the power that’s consumed by shipping cargo until you’ve stood inside a 1 megawatt propeller turbine –something that’s just barely capable of moving one supermarket-night’s worth of groceries to your home town.

There are many things that the shipping industry does which we take for granted, and it’s not hard to over look all the intricacies that go into delivering your 99 cent toy from China to the United States. None of it would be possible however without the dedicated work of people who keep our vessels away from the endless assault on structural integrity that is the world’s ocean water.

The current status quo is that ships are disposable assets, that are good for a few decades and then are to be scrapped. It begs the interesting question, how would you build more durable vessels? There’s a lot of opportunity in solving that puzzle. ∎

This project wouldn’t have been possible without the dedicated help of,

Jeremy Coon

Sean Greenslade

George

Ulrich Gall

John Heisey

Stephen Scholberg

Ian McNanie

Imma DeLa Cruz

Ryan Sternlicht

And all the amazing individuals at the Mare Island Dry Dock facilities

As adventurous as fixing this boat was, as soon as I wasn’t useful to them anymore, I was kicked out by the "captain".

I’m really mad. I was led to believe I was building some kind of startup incubator.

Instead, I was lied to and used.

During my time on the MV Maritol, I lost my sense of self. I was told I was a "ruined entrepreneur", that my "judgement was poor", and all other kinds of mean things I now recognize as gaslighting to make me feel subservient.

The boat was close to leaking petroleum in the SF bay due to neglect, as parties were more important than responsible ownership, so I felt moral obligation to fix it. I was naïve and convinced I had to fit in with the Silicon Valley elite or be thrown out of the venture capital networks.

At these parties the captain was famous for hosting I was pressured into sex acts. I feel like I was used to gain trust among others who were pressured into intimacy as well, and it left the relationships between those friends really fucked up. This I’m most frustrated with. Putting the health of other people in jeopardy for personal gain is just plain

evil.

If that wasn't enough, asking your business partner tell me to take down this post because you want to sell the boat and profit yourself, from what we all worked on

together?

And I am the one

tainting its image?Sorry, actions have consequences.